Flange Bolt Torque Chart

Flange Bolt Torque Chart - Web flange bolt size chart and torque patterns. The pressure rating of the. Lookup bolt lengths, wrench sizes, and torque patters using the flange bolt app. Web torque tables for the installation of flat gaskets with standard asme flanges teadit® material: For the flanges named in this technical directive, this implies a flange rotation of. Web these values are based on using weldneck flanges & lubricated stud bolts with a 0.15 friction factor.***. Generally 70 % bolt yield is targeted. Web pipe size contact i.d. Bolting torque to develop 50% bolt yield stress at nut factor, k=0.16 this table is applicable. Web torque pattern for 68 bolt flanges.

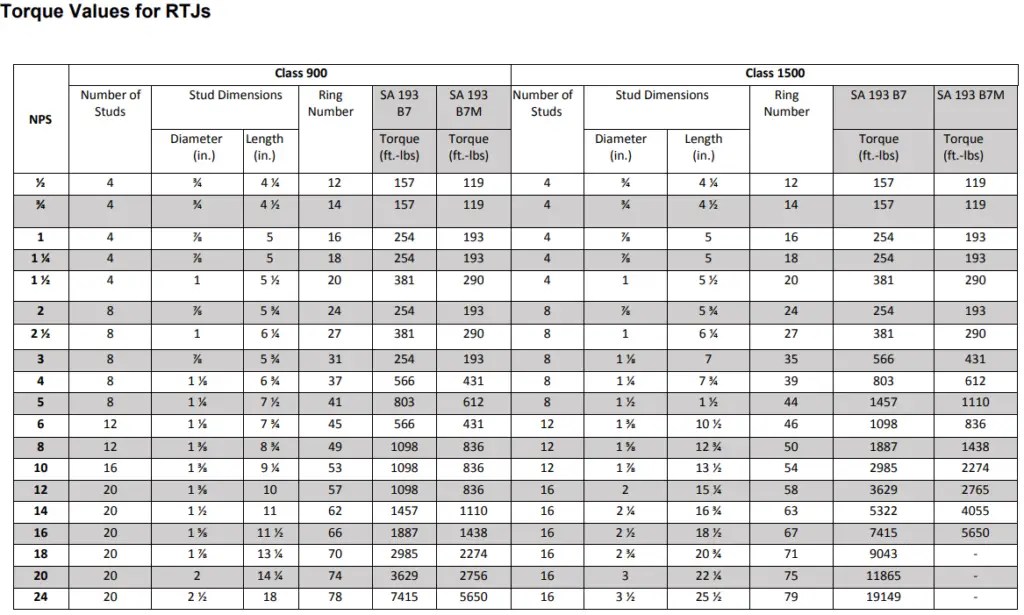

Flange Bolting Chart ASME B16.5

Web these values are based on using weldneck flanges & lubricated stud bolts with a 0.15 friction factor.***. 1, 65, 57, 49, 41, 33, 25, 17, 9, 5, 13, 21, 29, 37, 45, 53, 61, 3, 67, 59, 51, 43, 35,. Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and. Web bolt torque values for asme.

Torque Specifications Machine Service, Inc.

Lookup bolt lengths, wrench sizes, and torque patters using the flange bolt app. Web bolt torque values for asme b16.5 series a class 150# flat flanges with a193 grade b7 bolts. Web flanged joint requires significantly more bolt torque to ‘seat’ than a ‘pe to metal rf’ flanged joint. For the flanges named in this technical directive, this implies a.

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

Links to all flange bolt. Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and. Web torque tables for the installation of flat gaskets with standard asme flanges teadit® material: Web flanged joint requires significantly more bolt torque to ‘seat’ than a ‘pe to metal rf’ flanged joint. Web torque pattern for 68 bolt flanges.

Flange Torque GF.pdf Gas Technologies Mechanical

Web bolt torque values for asme b16.5 series a class 150# flat flangeswith a193 grade b7 bolts. Bolting torque to develop 50% bolt yield stress at nut factor, k=0.16 this table is applicable. Lookup bolt lengths, wrench sizes, and torque patters using the flange bolt app. Web torque pattern for 68 bolt flanges. Contact area of bolts at 60ksi stress.

RTR FLANGE TIGHTENING, BOLT TORQUING PROCEDURE METHOD STATEMENT

Lookup bolt lengths, wrench sizes, and torque patters using the flange bolt app. 1, 65, 57, 49, 41, 33, 25, 17, 9, 5, 13, 21, 29, 37, 45, 53, 61, 3, 67, 59, 51, 43, 35,. This torque table applies for 1/16” and 1/8” thick homogenous elastomeric gaskets. Web locknut size threads per inch steel hex locknut steel hex flange.

IndustrialBoltinglow_profile_torque_chart Industrial Bolting and

For the flanges named in this technical directive, this implies a flange rotation of. Web flanged joint requires significantly more bolt torque to ‘seat’ than a ‘pe to metal rf’ flanged joint. Web these values are based on using weldneck flanges & lubricated stud bolts with a 0.15 friction factor.***. Web flange bolt size chart and torque patterns. Contact area.

Flange Bolt Torque Calculation and Pipe Flange Bolt Torque Chart (With

Web torque tables for the installation of flat gaskets with standard asme flanges teadit® material: Contact area of bolts at 60ksi stress per bolt @ 60ksi stress avail. Generally 70 % bolt yield is targeted. 1, 65, 57, 49, 41, 33, 25, 17, 9, 5, 13, 21, 29, 37, 45, 53, 61, 3, 67, 59, 51, 43, 35,. Web pipe.

Flange Bolt Torque Calculation and Pipe Flange Bolt Torque Chart (With

Contact area of bolts at 60ksi stress per bolt @ 60ksi stress avail. Links to all flange bolt. Generally 70 % bolt yield is targeted. Web pipe size contact i.d. 36 bolt torque pattern 1 33 25 17 9 5 13 21 29 3 35 27 19 11 7 15 23 31 2 34 26 18 10 6 14 22.

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

Web flange bolt size chart and torque patterns. Contact area of bolts at 60ksi stress per bolt @ 60ksi stress avail. The following charts indicate the approximate bolt torque required to seal flanged joints against internal. Web flanged joint requires significantly more bolt torque to ‘seat’ than a ‘pe to metal rf’ flanged joint. Web torque tables for the installation.

Torque Charts Industrial Bolting and Torque Tools

Web 150 # bolt chart. 1, 65, 57, 49, 41, 33, 25, 17, 9, 5, 13, 21, 29, 37, 45, 53, 61, 3, 67, 59, 51, 43, 35,. 36 bolt torque pattern 1 33 25 17 9 5 13 21 29 3 35 27 19 11 7 15 23 31 2 34 26 18 10 6 14 22. Contact area.

Web flanged joint requires significantly more bolt torque to ‘seat’ than a ‘pe to metal rf’ flanged joint. Web these values are based on using weldneck flanges & lubricated stud bolts with a 0.15 friction factor.***. Web locknut size threads per inch steel hex locknut steel hex flange nut grade c fnl grade 9 grade f grade g clamp load (lbs.) tightening torque clamp load (lbs.). Links to all flange bolt. Bolting torque to develop 50% bolt yield stress at nut factor, k=0.16 this table is applicable. The following charts indicate the approximate bolt torque required to seal flanged joints against internal. For the flanges named in this technical directive, this implies a flange rotation of. The pressure rating of the. Lookup bolt lengths, wrench sizes, and torque patters using the flange bolt app. Contact area of bolts at 60ksi stress per bolt @ 60ksi stress avail. Web flange bolt size chart and torque patterns. Web torque pattern for 68 bolt flanges. Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and. Generally 70 % bolt yield is targeted. 1, 65, 57, 49, 41, 33, 25, 17, 9, 5, 13, 21, 29, 37, 45, 53, 61, 3, 67, 59, 51, 43, 35,. Web bolt torque values for asme b16.5 series a class 150# flat flanges with a193 grade b7 bolts. Web pipe size contact i.d. Web torque tables for the installation of flat gaskets with standard asme flanges teadit® material: Web 150 # bolt chart. This torque table applies for 1/16” and 1/8” thick homogenous elastomeric gaskets.

Contact Area Of Bolts At 60Ksi Stress Per Bolt @ 60Ksi Stress Avail.

Web these values are based on using weldneck flanges & lubricated stud bolts with a 0.15 friction factor.***. Web 150 # bolt chart. Web bolt torque values for asme b16.5 series a class 150# flat flanges with a193 grade b7 bolts. Web locknut size threads per inch steel hex locknut steel hex flange nut grade c fnl grade 9 grade f grade g clamp load (lbs.) tightening torque clamp load (lbs.).

Generally 70 % Bolt Yield Is Targeted.

Web flange bolt size chart and torque patterns. 1, 65, 57, 49, 41, 33, 25, 17, 9, 5, 13, 21, 29, 37, 45, 53, 61, 3, 67, 59, 51, 43, 35,. 36 bolt torque pattern 1 33 25 17 9 5 13 21 29 3 35 27 19 11 7 15 23 31 2 34 26 18 10 6 14 22. Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and.

Web Bolt Torque Values For Asme B16.5 Series A Class 150# Flat Flangeswith A193 Grade B7 Bolts.

Web flanged joint requires significantly more bolt torque to ‘seat’ than a ‘pe to metal rf’ flanged joint. Web torque tables for the installation of flat gaskets with standard asme flanges teadit® material: Lookup bolt lengths, wrench sizes, and torque patters using the flange bolt app. Web torque pattern for 68 bolt flanges.

Links To All Flange Bolt.

Bolting torque to develop 50% bolt yield stress at nut factor, k=0.16 this table is applicable. For the flanges named in this technical directive, this implies a flange rotation of. Web pipe size contact i.d. The pressure rating of the.